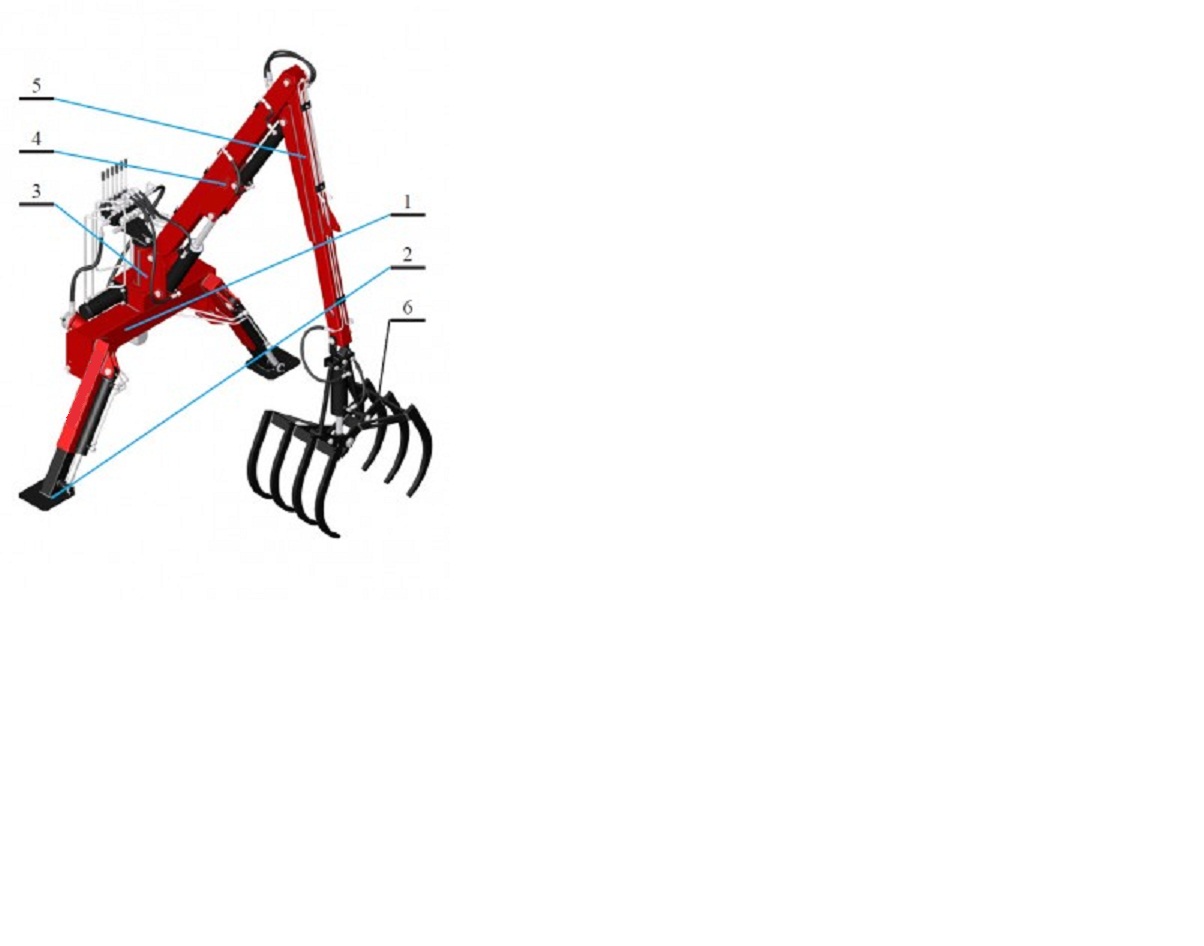

The carrier is a central element. It consists of rectangular steel tubes. In addition to being used for the acceptance of the loader to the tractor has a purpose of the oil. Carries hydraulic cylinders through which regulates the position of legs. It is also welded to the bracket and box rack through which the means of hydraulic cylinders turning Stub. The first arm and the second arm perform basic operations while manipulating the load. Each of them is a separate hydraulic cylinder. On the other hand, the snakes operating elements which opening also allows the cylinder hydraulic.

Regulating hydraulic cilindrare position, and therefore the burden of manipulation, is carried out by means of hydraulic manifold.

Hydraulic pump, which gives the working pressure starts output shaft of the tractor. The minimum required speed of the output shaft 540 r / min. In the case that the number of revolutions smaller there is a possibility of improper functioning of the loader.

Technical characteristics

CHARACTERISTICS OF VALUE

MAX. REACH 4 m

MAX. Lifting height 3.2 m

MAX. DEPTH REACH 2.4 m

MAX. WEIGHT LIFTING 300 kg

Rotation angle of 180 °

WHEEL WEIGHT 400 kg

Working pressure 160 bar

TANK CAPACITY 18 lit

MAX. Transport speed of 15 km / h

Tractor power required: 25 ÷ 35 kW

Note: In the basic price includes a fork, the price of accessories (buckets) is 250 euros in dinars.

Hydraulic utovarivačni – Preparation for work

Loader is connected to the tractor three-point and lift to transport position is controlled via the hydraulic system of the tractor. Bolt for the connection must be secured from falling out. A hydraulic pump connected to the output shaft of the tractor and chain to ensure anti-rotation around its own axis.

Before starting work, the loader is necessary to do the following:

1. Check the oil level in the tank

2. Lubricate all parts of ambulant

3. Lower the stabilizers on solid ground

4. Remove all people from the working area machines

5. Pre abstraction check all cargo operating positions machinery